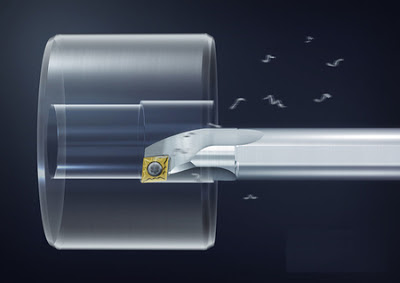

Boring Bar is a machine tool which is used in wood working and metal working. In various aspects of a building, the technique of boring is used. For centuries, boring has been used by the wood workers as a form of drilling. The Boring Tool in wood working is static in size and is utilized to form cuts with circular plunge. Boring is slightly different in metal working, because the resultant hole in metal working needs not to be circular in form. The tool in metal boring can be dragged and plunged on the Y and X axes to create a symmetrical or slot channel or hole or on the Z axis it can be moved only in the up and down motion for creating a hole of perfect circular in shape.

Modern tools for boring consist of three primary components though these are available in various differing designs. The parts of the tool used for boring include the graduated micro screw or dial screw, bar holder and the body. The body of the tool has two primary parts and the body is fabricated from solid stock. The tool’s top part presses or threads into the supporting shank. The bar holder or the lower part is interlinked through the dovetail, a smooth notch or T slots with an adjustment for the bore diameter through the dial screw. A larger cut is created by moving the cutting bits further out while the screw is adjusted.

Slight distortions can be created by this if further the cutting tool is moved than the boring head which is fabricated and designed for support. If the bearings used for supporting the tools have an undue wear or if there is great speed in the tool then it can cause an off balance effect and also can move the tool further away from the point of the center. If this happens it is known as unbalanced gyroscope precession. For giving a proper cut if the dial screw is adjusted then generally the set screw is utilized for resisting any sort of additional movement of the cutting head. Boring tool is the third basic part. These tools used for boring can be mounted horizontally or vertically in many designs of boring head.

Boring can be done by lathes, mills or drill press machines either with just a boring tool or with a boring head. The less distortion is created from unbalanced gyroscopic effect or from vibration if the distance is shorter between the material and the tool holder. The greater the dynamic or static mounts or the distance the tool will gain more flex which will raise the imbalance of the moving tool. The mass of the tool holder is increased by the use of a boring head. It will be at higher frequency if the vibration is created resulting in deflection of the tool which will make the desired path smaller and simpler to erase via passes of repetitive tool. The balance of the tool in press or mill of a dynamic tool can be adjusted with counterweights if the shaft is mounted perpendicular to the tool and the tool length can also be reduced.

All types of boring bar machines are available online. Persons interested can browse the internet to avail these machines directly from the manufacturers.

No comments:

Post a Comment